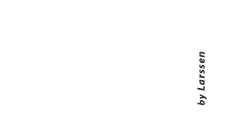

CMMS for CEA Operations: A Corporate Driven Maintenance Solution

What is a Computerized Maintenance Management System (CMMS)?

A CMMS is a software and technologically-driven maintenance strategy used by controlled environment agriculture facilities to seamlessly integrate a grow facility’s maintenance activities.

A CMMS effectively manages the delivery of a variety of processes intended to support the prevention of issues related to the maintenance of key infrastructure and equipment within the facility.

Availability, Optimization and Utilization

The goal of a CMMS is to capture valuable preventative maintenance, corrective maintenance, and failure information that is used to develop and optimize a company’s maintenance activities. The availability, optimization and proper use of equipment and facility infrastructure are the core elements of a CMMS that ensure all facility assets remain in working order.

CMMS and Business Improvement

Through the enactment of an effective maintenance plan, controlled environment agriculture facilities are able to engage in data-driven business planning that is guided by profitability. By minimizing downtime and through active prevention strategies, a CMMS is an essential tool that allows facilities to actively support and participate in their own business sustainability goals.

Learn more about CEAd, our vision, and Business Sustainability for Controlled Environment Agriculture Operations.

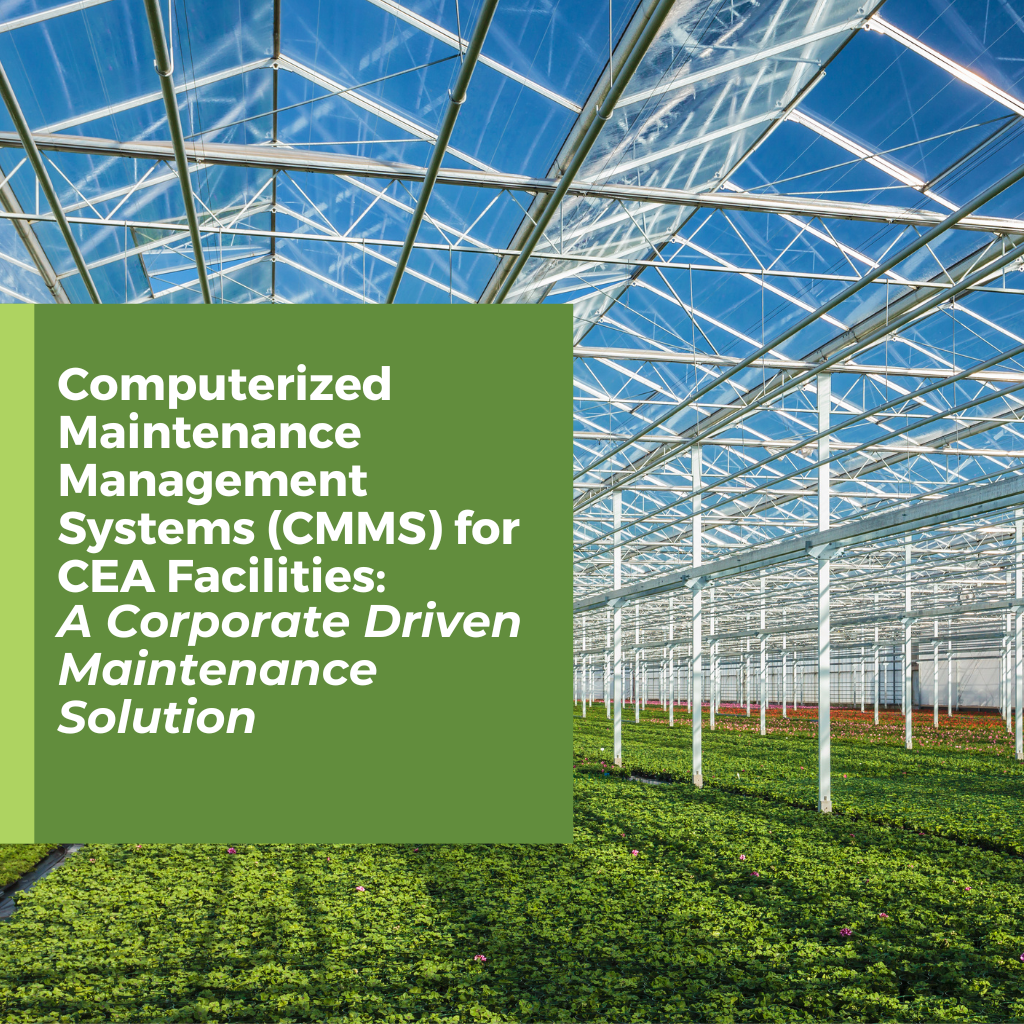

Benefits of a CMMS

- View and manage work orders, maintenance requests and preventative maintenance tasks.

- View and manage parts and equipment inventory.

- Streamline and strengthen workflows.

- Performance reports and track utilized labour and invoice costs

- Precise labour cost calculations & maintenance history reports.

- Optimization of facility management.

Getting the Most Out of a CMMS

Some of the key functions and features required to achieve success with a CMMS include:

- A user-friendly platform.

- Straightforward planning, scheduling, and budget functions.

- Inventory management feature.

- Data collection of key performance indicators (KPIs)

- Active and engaged support from upper management.

- A maintenance work process that is clearly defined and adequately structured.

Getting the Most Out of a CMMS

Some of the key functions and features required to achieve success with a CMMS include:

- A user-friendly platform.

- Straightforward planning, scheduling, and budget functions.

- Inventory management feature.

- Data collection of key performance indicators (KPIs)

- Active and engaged support from upper management.

- A maintenance work process that is clearly defined and adequately structured.

Three Key Elements of CMMS Success

- Defined Goals and Planned Outcomes – Establishing measurable goals allows for a smooth transition to a CMMS and enables reportable results and useful data.

- Employee and Management Accountability – Ensuring top management support and providing employee incentives for system uptake, are essential in encouraging the proper use of the system.

- Integration Support – Having an experienced third-party support the implementation of a CMMS alleviates possible complex integration problems.